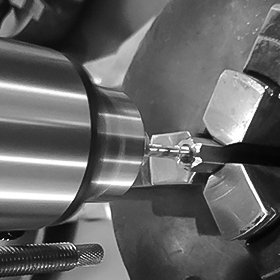

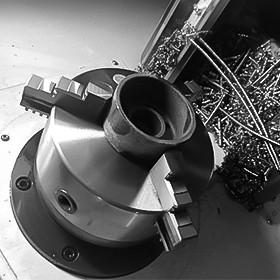

The bearing seat is a component used to support the shaft.

The bearing is installed in the bearing seat as a rotating part and only bears the thrust bearing of the axial load. At the same time bearing radial load and axial load is called radial thrust bearing.

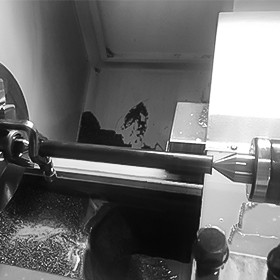

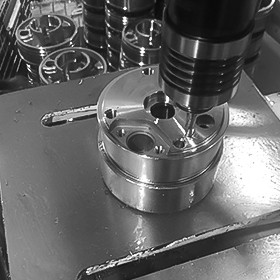

Select high-quality stainless steel material, (has the advantages of anti-rust, corrosion resistance and abrasion resistance.)

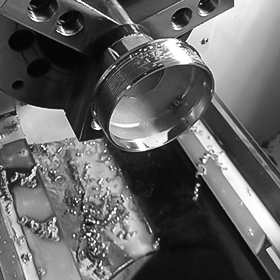

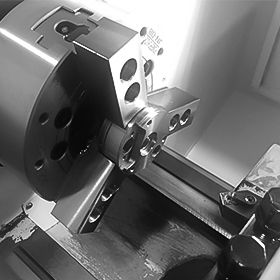

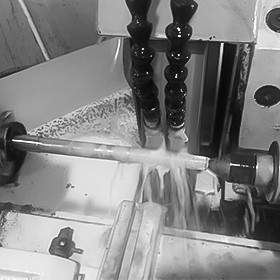

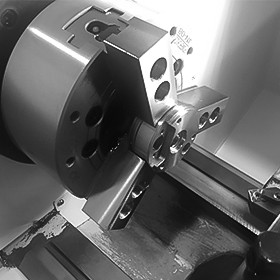

New machine tool processing (processing accuracy can reach 0.003mm) to ensure the accuracy requirements of the parts, and the concentricity requirements are 0-0.05mm. In order to ensure the concentricity of the motor and the pump body, the stability and balance of the pump movement should be increased.